In the heart of Load Sensor in Pakistan bustling industrial scene, a technological marvel is quietly revolutionizing the way businesses operate: load sensors. Imagine a device capable of measuring weight with unparalleled accuracy, transforming mundane tasks into streamlined processes. In this comprehensive guide, we embark on a journey to unravel the mysteries of load sensors, shedding light on their intricate workings and varied applications. weight sensor Pioneering Precision in Pakistan’s Industries.

Load sensors, often interchangeably referred to as weight sensors or load cell sensors, play a pivotal role in industries spanning manufacturing, logistics, agriculture, and beyond. Their omnipresence underscores their importance, making them a cornerstone of modern operations. By delving into the core principles behind these sensors, we illuminate the path for businesses seeking efficiency, accuracy, and innovation.

Information:

At its essence, a load sensor is a device designed to detect and measure force or load. These load cell sensors are engineered to convert mechanical Load Sensor in Pakistan, such as pressure or weight, into electrical signals. Ingenious designs enable this conversion. Strain gauges, arranged in a Wheatstone bridge setup, detect tiny deformations from applied force. These nearly invisible deformations become accurate electrical readings. Such meticulous measurements find applications in diverse sectors, including but not limited to, industrial automation, healthcare, and transportation.

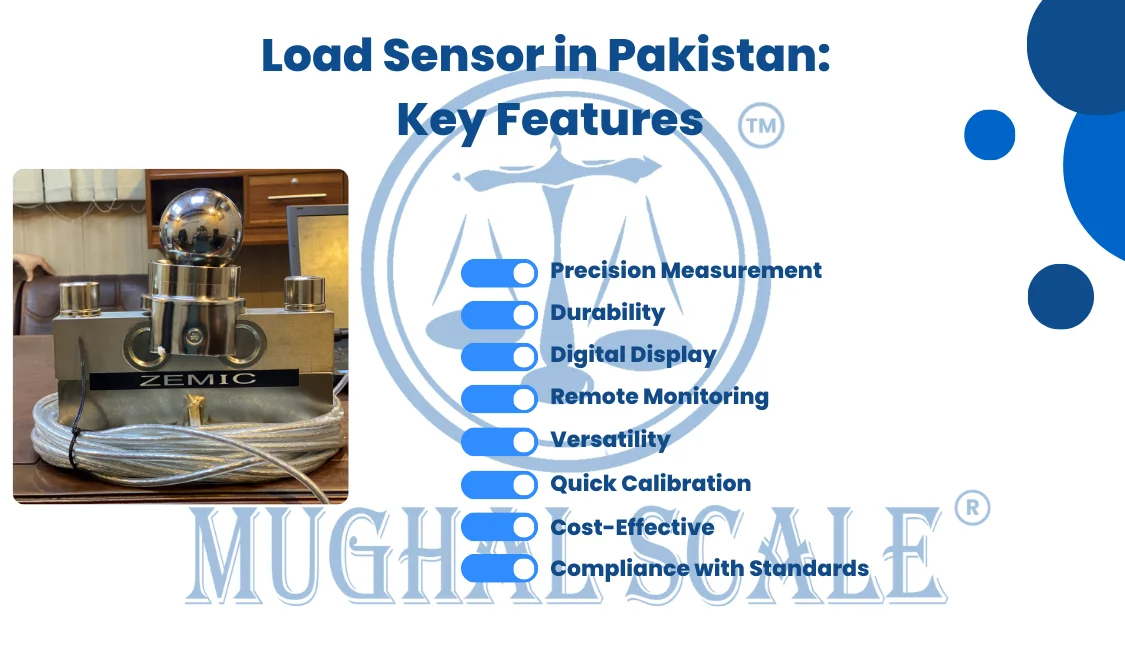

Key Features:

| Features | Description |

| High Precision | Accurate weight measurement for critical tasks |

| Robust Construction | Withstands harsh environments |

| Versatility | Adaptable to various applications |

| Digital Interface | Seamless integration with digital systems |

| Overload Protection | Safeguards against excessive loads |

| Temperature Compensation | Reliable performance in diverse climates |

| Low Power Consumption | Energy-efficient operation |

| Easy Calibration | Simple setup and calibration procedures |

Why To Choose Us:

- Proven Results: Our track record speaks volumes, showcasing successful implementations of load sensors across diverse sectors. Businesses have witnessed tangible improvements in efficiency and productivity, bolstered by our expertise.

- Customized Strategies: Recognizing the unique needs of each client, we tailor our solutions to address specific challenges. Our customized approach ensures that businesses receive optimal results, aligning seamlessly with their objectives.

- Expert Team: Behind our success story stands a team of seasoned professionals well-versed in weight sensor technology. Their expertise guides clients through the implementation process, offering valuable insights and support.

- Cutting-Edge Tools: Embracing the latest advancements, we provide access to cutting-edge load sensor technologies. By staying ahead of the curve, we empower businesses to thrive in a competitive landscape.

- Maximize ROI: We understand the significance of return on investment. Through our solutions, businesses not only enhance operational efficiency but also maximize their ROI, ensuring long-term sustainability and growth.

Detailed Overview of Load Sensor in Pakistan

In the intricate tapestry of load sensors, numerous applications unfold. From industrial automation, where these load cell sensors facilitate precise material handling, to healthcare, where they contribute to advanced medical equipment, the impact is far-reaching. Moreover, in agricultural contexts, weight sensor aid in monitoring crop yields and ensuring optimal irrigation, enhancing overall agricultural productivity.

The digital era has ushered in a new wave of possibilities for Load Sensor in Pakistan. Integrated seamlessly with Internet of Things (IoT) platforms, load sensors provide real-time data, enabling remote monitoring and predictive maintenance. This interconnectedness not only improves operational efficiency but also minimizes downtime, a crucial factor for businesses striving for continuous production.

The Ultimate Guide to Lead Generation:

- Identifying Target Markets: Before implementing load sensor technology, businesses must identify their target markets. Understanding the specific industries and applications where load sensors are indispensable ensures strategic deployment.

- Building Partnerships: Collaboration with manufacturers and suppliers of load sensors is key. Establishing strong partnerships ensures a smooth supply chain, guaranteeing access to high-quality load cell sensors and prompt support services.

- Educating Stakeholders: Knowledge dissemination among stakeholders is paramount. From engineers responsible for sensor integration to decision-makers shaping business strategies, educating all stakeholders fosters a shared understanding of the technology’s potential and benefits.

FAQs of Load Sensor in Pakistan

Q1: What are load sensors used for in industrial automation?

A: Load sensors are important for tasks such as weighing materials, monitoring conveyor belts, and ensuring accurate dispensing in industrial automation. Their accuracy and reliability make them indispensable in optimizing manufacturing processes.

Q2: Can load sensors be used in hazardous environments?

A: Yes, load sensors are available in rugged, corrosion-resistant designs, making them suitable for hazardous environments. These sensors guarantee smooth operation in challenging environments by enduring tough conditions.

Q3: How are load sensors calibrated?

A: To calibrate load cell sensors, we use known weights and calibration equipment. During the calibration process, we compare the output of the weight sensor to the expected value and make any necessary adjustments. Proper calibration is crucial for accurate weight measurements.

Q4: Are load sensors compatible with digital systems?

A: Yes, modern load sensors come with digital interfaces such as USB, RS-232, or Ethernet, enabling seamless integration with digital systems. This compatibility facilitates real-time data transmission and analysis, enhancing operational efficiency.

Q5: What is the lifespan of load sensors?

A: The lifespan of load sensors depends on factors such as usage, environmental conditions, and maintenance. With proper care and regular maintenance, load sensors can last for several years, providing reliable performance throughout their operational life.

Conclusion of Load Sensor in Pakistan

In the vibrant landscape of Load Sensor in Pakistan industries, load sensors stand as beacons of innovation and efficiency. Their ability to transform raw force into actionable data has reshaped how businesses approach tasks, making processes more streamlined, accurate, and reliable. As we conclude this exploration, it is evident that embracing load sensor technology is not just an option but a necessity for businesses aiming to thrive in the modern era.

In this guide, we have traversed the intricate world of weight sensor, unraveling their complexities and showcasing their myriad applications. From the foundational principles to the diverse sectors they impact, load cell sensors have become indispensable tools, propelling businesses toward unprecedented heights of success.